Power cable selection and measurement.

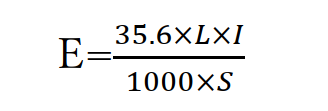

It is easy to calculate the voltage drop value, if you know the length, cross-sectional area, and the current value going to be sent, by using the formula below.

E:Voltage drop within the cable(V) L:Length of the cable(meter)

I:Electric current(A) S:Cross-sectional area of the cable(sq)

For example,

Case 1)Cable:Size – AWG16, length -10 meters

Electric current to be sent:0.5A

Calculation : E=(35.6 X 10 X 0.5)/(1000 X 1.25)=0.1424(V)

Case2)Cable:Size – 2sq, 15meters Electric current to be sent:1.2A

Calculation : E=(35.6 X 15 X 1.2)/(1000 X 2)=0.3204(V)

So let’s use this calculation to think about how to select which cable size to use.

Conditions are as below.

・Electric current and voltage at sender-side:+24.0V , 2.0A

・Length of the cable:12m

・Requirement of the power source voltage of the receiver-side (the receiving device):+23.0±1.0V

What to consider here is ; How much voltage of electricity will actually be received by the receiving device?

As you can see in the requirement, at least +23.0V of voltage is needed.

Now, we know that the sender-side voltage is +24.0V. Which means that the voltage drop value needs to be lower than 1.0V.

First, let’s calculate the voltage drop using a 1.25sq cable.

E(1.25)=(35.6 X 12 X 2)/(1000 X 1.25)=0.684(V)

Next, with a 1sq cable.

E(1.0)=(35.6 X 10 X 0.5)/(1000 X 1)=0.854(V)

Next, with a 0.75sq cable.

E(0.75)=(35.6 X 10 X 0.5)/(1000 X 0.75)=1.139(V)

From the calculations, we can see that the voltage drop value is higher than 1.0V if we use the 0.75sq cable.

Which means we should not use a 0.75sq cable.

We should use a 1.0sq or a 1.25sq cable – considering the margin needed, 1.25sq cable is more recommended.

You can use this calculation as a basic way, and please note that the actual resistance value of cables would change with the temperature, and that you will need to have even bigger margin for devices with higher inrush current.